Thermal Spray: Most Commonly Asked Questions

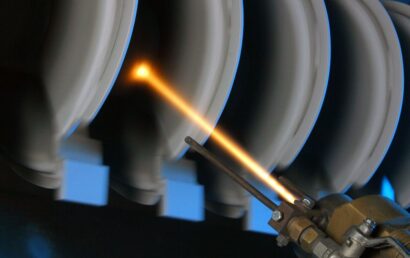

As an oversimplified explanation: When specific materials are delivered at high speeds onto a chosen surface, and the particles being delivered spread out to adhere and form a coating, this is known as thermal spray. Unlike in the early days of thermal spraying, the material being applied no longer needs to be in a liquid or molten state. In fact, powder is contained in certain coatings which are thermal sprayed through today’s methods.

With that condensed definition of thermal spray, let’s take a look at some of the most commonly asked questions when it comes to thermal spray and the coatings that can be provided through the process.

What Are the Classifications Of the Thermal Spray Process?

The thermal spray process is classified through the following categories:

- Detonation gun

- Plasma spraying

- Arc spraying

- HVOF or high velocity oxy fuel spraying

- Flame spraying

- Cold spraying

Which Materials Are Most Commonly Used in This Process?

First of all, materials that are applied through the thermal spray process can be in either a liquid or solid state. During spraying, if a material cannot remain stable, and heat is involved, it cannot be used as is. The decomposition or oxidation of a material is what is meant by instability. The unstable material can be used as long as, in order to protect the reactive or unstable material, a second material is utilized.

Is One Coating All That Is Needed?

Coatings can exist in various thicknesses. To achieve a thicker coating, numerous coats are sometimes applied. There are any number of factors that dictate the thickness of a coating from the size of the feedstock to the requirements of a specific part or component.

Is the Bonding Process Ever A Problem? What Influences It?

Keep in mind that the surface to which a coating is thermal sprayed must be prepared properly (i.e. extremely clean). The particle or droplet being sprayed bonds chemically with the substrate or underlying surface. If a chemical bond cannot be produced, in order to create a mechanical bond, the substrate is roughened. The underlying surface and the particles or droplets literally interlock.

Several factors dictate bonding strength:

- How the sprayed material (feedstock) reacts with an underlying substrate

- The roughness of the substrate

- The thermal spray plume’s inner temperature

- The speed of the (thermal sprayed) particle

Compared to Other Coating Technologies, What Are Thermal Spray’s Advantages?

Thermal spray technologies out do coating technologies from years past in the following ways:

- Certain materials’ decomposition may be avoided due to the speed of cooling and heating.

- Many paints produce/contain volatile organics which are not present in the thermal spray technique.

- Materials at extremely high melting temperatures are safely and easily deposited through this process.

What Forms Can Thermal Sprayed Materials Take?

The material being thermal sprayed is known as feedstock and can take several forms:

- Liquid

- Ceramic rods

- Composite or metal wire

- Ceramic, composite, metal, or plastic powder

What Are The Most Common Uses for These Types of Coatings?

Applications most commonly seen consist of the following:

- Electronic applications

- Worn components reclamation

- Artistic – bronze application, glass coloring, etc.

- Printing industry i.e., ink transfer rolls

- Abradables such as in the aviation industry

- Anti-corrosion coatings i.e., infrastructure and marine environments

- Thermal barrier coatings such as those used in combustion engines

- Biomedical i.e., cancer therapy, dentistry, orthopedics, etc.

- Abrasion and wear resistance coatings such as those used in mining

If you have any questions about thermal spray or the coatings that can be applied through that process, do not hesitate to contact us at A&A Coatings. Our knowledgeable, helpful individuals will be happy to assist you.