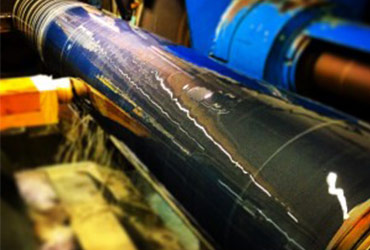

Thermal Spray Process Showcase | Electric Arc Spray

At A&A Coatings, we specialize in different types of thermal spray coatings that are achieved through a variety of thermal spray processes. For example, we can perform the metalizing process to spray metal onto different product surfaces. Under the metalizing technique, we often use the electric arc spray process to create metallic coatings for either decorative or functional purposes, or both. In this process showcase, we will talk about the electric arc spray process.

What is Electric Arc Spray?

Also known as twin wire arc spray, electric arc spray is a process in which two wires that are made of desired materials (acting as electrodes) will be simultaneously fed through a spray gun. With a molten arc between both the wires now, the gun is connected to a high-current power source so that it can trigger an atomization of the now-molten material and propel this material onto the substrate to form the coating.

What are the Capabilities of Our Electric Arc Spray Process at A&A Coatings?

Our electric arc spray process is considered as an energy efficient one due to all the input energy is utilized to melt the desired materials. A&A Coatings can create metallic coatings with mechanical bonds up to 5000 P-S-I or semi-metallurgical bonds. We guarantee that there will not be distortion because the process does not subject the substrate to temperature over 250°F.

What Types of Materials Can You Choose for the Electric Arc Spray Process?

If you request for the electric arc spray process, you can then choose any types of materials you desire that feature melting points under 10,000°F. A&A Coatings has a wide portfolio of materials that you can select for the electric arc spray process which include but not limited to:

- Alloys

- Superalloys

- Pure metals

- Wear resistant carbide materials

Well, you do not have to worry if you do not know which material you should choose for your coatings. This is because our materials engineers will be assisting you at every stage of your order, including the material selection phase. Our wire materials also come in different wire diameters so that we can accommodate a wide spectrum of clients’ needs and requirements.

The Functionalities You Can Achieve with Electric Arc Spray Coatings

There are so many different surface functionalities you can benefit from when you choose the electric arc spray process. Here’s a short list of such functionalities and it’s by no means an exhaustive one:

- Corrosion resistant

- Erosion resistant

- Oxidation resistant

- Low friction surfaces

- Electrical conductivity

- Resistant to different corrosive environments

- Decorative purposes

- EMI/RFI shielding

- Anti-skid surfaces

Choose the Electric Arc Spray Process for Your Coatings Today!

It’s no secret that the electric arc spray process is known as a super efficient, economical and quick solution to your coating needs. As mentioned earlier, only atomizing air is used alongside electricity, and no other types of gases is used. This enables you to experience characteristically clean and highly machinable coatings compared to those produced by other thermal spray coating processes.

We at A&A Coatings have a good range of industrial grade electric arc spray equipment to carry out this metalizing process and with our experience for more than 70 years in addition to our huge inventory of materials you can choose from, we are highly confident that we can meet all of your coating needs, even if you have highly specialized application requirements.

Call or email us today to find out more about utilizing the electric arc spray process for your coatings!