How Surface Engineering Solves Key Challenges With Valves

Surface engineering can be defined as the design of a surface treatment which provides an enhancement to the substrate. It is a crucial technology at the foundation of improving performance, life-cycle cost, and longevity of valves and their components.

Corrosion of Valves

Valves are constantly bombarded by chemicals such as, but not limited to, alkalis or acids which attack many critical components. Additionally salt water environments and other atomospheric conditions can cause corrosion.

Prevention of Corrosion of Valves

To protect valves from atmospheric corrosion materials such as Aluminum, Zinc, Zinc/Aluminum Alloys can be applied. For chemical corrosion protection materials such as Chromium Carbide, Chrome Oxide Ceramic and others can be applied to maximize the service lifespan of the valve.

Erosion and Wear of Valves

Many valves are operating continuously 24/7 and are subject to the scouring and burnishing action of a continuous flow of liquid at high velocity. Over time, this can lead to erosion and wear of valves and their components. Additionaly liquids containing some amount of contamintation or solids can present a large risk of wear.

Resistance to Erosion and Wear of Valves

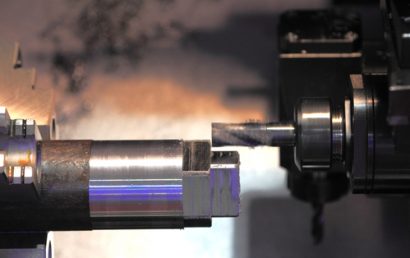

Erosion and Wear resistance are two hallmarks of thermally sprayed coatings. Both via the Plasma Spray and HVOF coating processes A&A Coatings can apply Tungsten Carbide, Chromium Carbide, Ceramics and many hard alloys which will resist wear in many different environments.

Seizure of Valves

Malfunctioning of valve occurs mostly when fluids containing sold, gummy materials stick to the discs or the seating of the valve as is the case in some food processing plants. Also, if the valve is kept in the shut or open position for a long period of time, the build-up of this sticky substance takes place and solidifies around the disc thus preventing the operation of the valve.

Prevention of Seizure of Valves

Quick release, anti-friction coatings can be applied to various valve components to eliminate this problem. Furthermore quick release coatings can be applied on top of some of the materials mentioned above to provide wear/erosion resistance, corrosion resistance AND anti-friction.