Are Thermal Spraying, Maintenance-Free Robots Science Fiction or Reality?

Once upon a time, a world of robots was what science fiction novels were made of. These days, robots (or robotics) are used in numerous industries. But until they are maintenance-free, they will still rely on humans for any number of things. Currently on the horizon, however, could be a way to make robots more self-sufficient. Maintenance could be reduced when robots can resist particle spray and heat.

Co-Bots or Robots

Though seemingly exclusive pick-and-place solutions in years past, co-bots (or collaborative robots) these days are relatively versatile and are popping up everywhere. They are no longer limited to conveyor belts and clean rooms. Today’s robo-arms are more portable, lighter, and smaller. And they are showing up in hazardous environments at an increasing rate.

Co-bots Are Being Used To Apply Protective Coatings

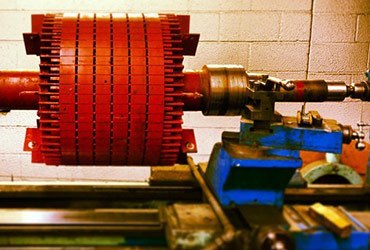

Why use a robot? Because thermal spray (and other) processes produce metallic particle spray and high temperatures, they tend to be hazardous to humans. But they are hazardous to robots, too. A solution needed to be found to reduce maintenance on robots who incurred damage resulting from these circumstances.

For several years now, one particular co-bot has been used in aviation component repair. ATI (Aircraft Tooling, Inc.) has employed the UR10 (a Universal Robot co-bot model) for just such purposes. To restore and improve component surfaces, plasma spray coating processes and HVOF (High Velocity Oxygen Fuel) thermal spray are being applied by UR10.

UR10 – Our Special “Boy”

What’s so special about UR10? It has required no preventative maintenance. It can work in extreme environments, is rated for high temperatures, and sealed against dust. This is impressive because tungsten carbide, used in some powder coatings, is a hard metal coating. It was originally thought that co-bots would be destroyed if it seeped into their bearings. But after years of operation, no particles are showing!

Apparently, co-bots aren’t as fragile as their reputation led people to believe. They are more durable in extreme environments than many originally assumed. Old-school robots worked well in a clean room but today’s co-bots, because they are rated for high temperatures and sealed against dust, work just as well in their own, extreme environments.

And what is truly amazing is that within four hours of unpacking your UR10, your team can get it up and running and fully functional. A little unpacking and programming is all that is needed.

UR10s Are Money Savers and So Much More

Many of the traditional industrial robots that have been used in the past are simply unable to meet the current needs of certain industries. For one thing, costs are outrageous. What’s more, they require safeguarding, they were hard to program, and could not be moved easily between cells because they were far too bulky (particularly the cast-iron models).

UR10 has other family members which include the UR5 and the UR3. Each co-bot’s payload in kilograms is signified by its name. The UR10 and was chosen by ATI because it was advantageous to them. They could keep the floor clear because they could walk underneath the co-bot, as it can hang upside down. It was also employed because of its length.

No one understands the benefits of thermal spray protective coatings more than A and A Coatings. And while UR10 may not be employed here, we do have experienced, expert staff to assist you with all of your protective coating needs. Contact us today to see how we can be of assistance to you and your company, and to discover the benefits we bring to your industry.