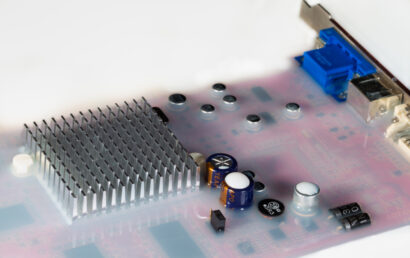

Thermal Coating Extends The Life Of Circuit Boards

Under ideal circumstances, PCBs or printed circuit boards usually work well – at least electrically. But environmental variables can quickly deteriorate the performance of the best PCB. These variables can include moisture, debris, dust, dirt, temperature, etc. The performance of printed circuit boards can also be severely diminished by power surges, power overloads, and accidental impact. The longevity and reliability of these circuit boards is reduced through gradual corroding and degrading as a result of some of these factors. In an effort to alleviate such problems, engineers and manufacturers decided to attempt to protect PCBs against the environment with something called conformal coating.

What Is Conformal Coating?

This term refers to a nonconductive, protective dielectric layer that is usually applied to PCB assemblies through brushing, dipping, or spraying. The coating protects against damage from extreme or harsh environments. During its operation, a PCB’s life can be prolonged through the use of conformal coating because damage from rough handling and installation can be somewhat prevented. It also helps reduce thermal and mechanical stress.

Properties of Conformal Coating

In order for conformal coating to protect a PCB, it is essential that the coating have certain characteristics: mechanical durability, low moisture permeability, good thermal properties, good chemical resistance, and good electrical properties. Additionally, a conformal coating that is ideal for the protection of a PCB will adhere well to the components and board materials that populate the board.

PCB Masking Requirements

Various materials can be used in different masking techniques during the conformal coating process: liquid latex, boots, shapes, dots, masking tape, etc. There are different masking requirements for Parylene coated CBCs than there are for liquid applications. A basic shielding from the applied liquid is what is needed during liquid masking. But masking needs to be sealed and airtight for Parylene coating.

When the dip method is used for processing PCBs, exceptional circumstances apply. Unwanted coating cannot get on the connectors, so leakage must be prevented. Proper sealing needs to be done to masked areas. (If problems arise, coating removal methods are in existence.)

Everything Has Its Limits

There are certain limitations to conformal coatings, however. Their performance can be affected by

atmospheric pollutants, moisture, flux residue, or fingerprints being present on the surface of the PCB prior to the sealing or coating process. This is why it is of the utmost importance that, in order to ensure efficient, long-term performance, cleaning and drying of each PCB is done prior to the application of coating.

Conformal Coatings – Five Most Common Types

Most commonly used are the following five conformal coatings:

Parylene – though difficult to remove and requiring specialized vacuum chambers… this coating offers no curling, complete coverage, is durable, strong, and ultra-thin.

Epoxy – though reworks are nearly impossible, it has a short pot life, and requires precise mixing… it offers abrasion and humidity resistance, is very rigid, and has excellent mechanical strength.

Silicone – though the residue is difficult to remove, and it offers poor mechanical strength and abrasion resistance… it is flexible and offers excellent resistance to humidity and temperature.

Polyurethane – though it can be rigid, is moisture sensitive, and difficult to remove, when compared to acrylics… it offers better solvent resistivity, higher mechanical strength, and excellent resistance to humidity.

Acrylic – though it offers low mechanical strength and poor resistance to temperature and solvents… it is easy to rework, resist abrasion and moisture, dries rapidly, is easy to apply, and is inexpensive.

When it comes to protective coatings, the experts at A and A Coatings know exactly what is needed for every industry. If you would like to find out more about what protective coatings can do for you and your company, contact the knowledgeable and experienced professionals at A and A Coatings today.