Protect Your Pipelines From Corrosion With Thermal Sprayed Aluminum

CUI (or corrosion under insulation) is a major problem in the pipeline systems used in the petrochemical industry. But thermal sprayed aluminum is helping reduce the maintenance budget so severely impacted as a result of that corrosion.

Where Does All the Money Go?

The petrochemical industry knows exactly where the money goes!

Far too much money is spent annually on pipe replacements, pipe painting, removal and reinstallation of insulation, external piping inspections, etc. A strategy that was both reliable and long-term had to be developed to prevent CUI. Maintenance costs could be significantly reduced if maintenance free and inspection free piping systems could be created.

Enter thermal sprayed aluminum (TSA) coatings. Adopted by any number of petrochemical industry operators is metallization flame spray equipment as a method of better protecting pipelines. Compared to other systems, it is a far more cost-effective solution. It protects against CUI and atmospheric corrosion, long-term.

Projects for which this method has proved beneficial are as follows:

- Work being done on a live operating plant

- Full range of vessels and pipes

- Lube oil transporting marine jetty pipeline

- and many, many more

Preparation Is a Critical Step

If the surface of the pipeline is not prepared appropriately, the thermal spraying process may not succeed. In the case of pipelines, grit blasting is used to prepare the surface. This assists with TSA bonding. After blasting, visual inspection is done on the surface with 10 X magnification. This checks the surface finish and cleanliness. To make sure that the blasted surface is not contaminated, a tape test is also done. No dust must be present on the tape. Finally, a test is done for salt contamination. Thermal sprayed aluminum can be applied once the pipelines have passed all of these tests.

What Does Thermal Spraying Involve?

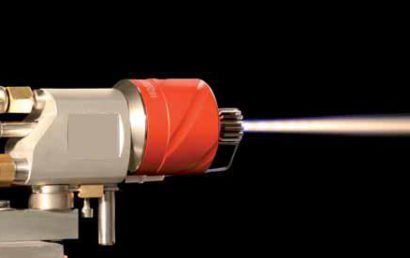

The process of thermal spraying involves small molten metal particles. They are propelled onto a surface that has been blast prepared. The particles flatten upon contact with the surface. They then freeze and bond mechanically both to each other and to the blasted surface. Bonding increases as the thickness of the coating increases. A heat source is used to create the molten particles required. Also required are projections/automatization methods in order to spray the material. One such process used in many instances is a flame spray process.

Arc spray, plasma spray, and HVOF are additional thermal spray techniques. Every technique has its pros and cons, which is why any industry looking into thermal spray protective coatings should consult a professional thermal spray company. This way, the best method possible can be determined as well as whether or not a custom material or technique should be used.

Over the decades, A&A Coatings has been involved in creating coatings that protect components, machinery, parts, and various surfaces involved in every industry in the world. We use the latest techniques and materials to give our clients the best thermal spray experience possible. If you would like to find out how your bottom line can be positively affected through the use of thermal spray coatings, contact us today. One of our knowledgeable representatives will be happy to tell you all about modern thermal spray techniques and how beneficial they have been in numerous settings.