Using Air Jets In Plasma Spray Coating Processes

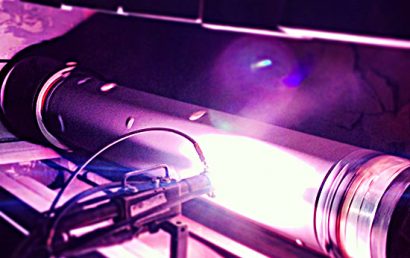

In the plasma spray coating process, a spraying heat source is needed. To create that heat source for thermal spray processes, and in order to generate a stream of plasma gas that is high-temperature and ionized, the process uses a DC electric arc. In a powder form, a coating material is then carried into the plasma jet in an inert gas stream. Here it is propelled toward the substrate after being heated. This is where the air jets come in.

An Explanation of the Plasma Spray Process

Gas becomes electronically conductive and ionized due (in part) to the high temperatures used in the plasma spray process. In the thermal spray coating industry, one of the leading processes is plasma spray. This is because it produces high-quality coatings by combining high temperatures, a high-energy heat source, an inert spraying medium, and high particle velocities. Ceramics, and other coatings that have melting points considered extremely high, are particularly useful in the plasma spray process.

Thermal Spraying – Variations

When it comes to thermal spraying, there are a number of variations that can be utilized. They are as follows:

- Cold spraying

- Warm spraying

- HVAF (high velocity air fuel)

- HVOF (high velocity oxy-fuel coating spraying)

- Flame spraying

- Wire arc spraying

- Detonation spraying

- And finally, plasma spraying

Why Do Industries Use Plasma Spray Coatings?

The benefits of these coatings are many. But one of the biggest benefits is that the process can spray any number of materials; from high melting point ceramics, to carbides, to pure metals. Of course, there is more. Other benefits include the following:

- Protect against corrosion

- Wear resistance

- Clearance control (abrasives and breakables)

- Heat resistance and oxidation

- Temperature management

- Resistivity and electrical conductivity

Materials Used In Plasma Spray Processes

The following plasma spray materials can be used, depending on the needs of the client:

- Alumina-Titania Ceramic – Because this offers corrosion and wear resistance, it is used in applications such as industries that have to deal with seawater.

- Tungsten Carbide – One of the most wear resistant, hardest coatings in the thermal spray industry.

- Chromium Oxide Ceramic – The perfect choice for corrosion resistant, anti-galling, self-mating properties. Excellent candidates are parts affected by abrasive grains, particle erosion, and cavitations.

- Aluminum-Polyester – This coating has incredible internal strength and offers impact resistance with its unique blend.

Applications for Jet Sprayed Protective Coatings

Because these coatings offer numerous benefits including versatility, they have many applications. Here is just a very small sample of some of the uses for jet sprayed protective plasma coatings:

- Gas turbines – used to seal ring grooves on combustion hardware

- Laser engraving printing rolls – assist in the printing process and offers wear resistance

- Marine industry – provide resistance to pitting, corrosion, and wear on submarines and other ships

- Gas and oil industry – provide erosion, wear, and corrosion resistance on down-hole tools

At A&A Coatings, we do all kinds of thermal spraying. For over 70 years we have been a leader in our industry, providing countless other industries with protective coatings. Your business can significantly improve its bottom line through the use of thermal spray protective coatings on machinery, components, products, and various surfaces. Contact us today if you would like to find out more.