What Are The Benefits Of Thermal Barrier Coatings For Aeroengine Applications

Thermal barrier coatings for aeroengine applications offer significant advantages in the aviation industry. These advanced coatings protect critical engine components from extreme heat, enhancing the performance and efficiency of aircraft engines.

By applying these coatings, manufacturers can achieve better durability and longer lifespans for aero-engine parts, ultimately improving overall operational efficiency. These benefits are key for industries aiming to push the boundaries of performance and reliability in high-temperature environments.

Improve Aeroengine Efficiency By Reducing Heat Transfer

Thermal barrier coatings work by minimizing the amount of heat that penetrates into the engine components. These coatings create an insulating layer, preventing excess heat from reaching critical parts. By doing so, the engine can operate at higher temperatures without risking damage to its components.

The reduction in heat transfer contributes directly to improving the overall efficiency of the engine. When an engine stays cooler, it performs better, which is a key advantage for industries looking to enhance machinery performance under extreme conditions.

Enhance Engine Component Durability And Lifespan

Thermal barrier coatings extend the lifespan of aero-engine components by protecting them from the damaging effects of extreme heat. Over time, excessive heat can cause materials to degrade, leading to wear and tear. These coatings act as a protective shield, reducing the impact of thermal stress and corrosion.

An enhanced protection translates into fewer replacements of engine parts, resulting in lower maintenance costs and extended service life. Industries benefit by maintaining more reliable equipment that performs effectively over longer periods.

Increase Temperature Tolerance For Higher Performance Levels

Thermal barrier coatings allow aero-engine components to tolerate higher operating temperatures. With this added temperature tolerance, engines can achieve improved performance levels. In high-demand industries like aerospace, the ability to run engines at elevated temperatures without compromising component integrity is a major advantage.

The coatings make sure that parts can withstand intense heat while maintaining their structural strength, enabling higher efficiency and output. This boost in performance is critical for industries seeking to meet stringent performance and safety standards.

Reduce Fuel Consumption Through Optimized Engine Operations

Optimizing engine performance through the use of thermal barrier coatings directly impacts fuel consumption. When engines operate more efficiently, they require less fuel to maintain optimal performance levels. By improving the thermal management of engine components, these coatings enable engines to use fuel more effectively.

The reduction in fuel consumption not only lowers operational costs but also contributes to environmental benefits by reducing emissions. Industries that prioritize fuel efficiency will find thermal barrier coatings a valuable investment for their machinery.

Minimize Maintenance Needs And Operational Downtime Risks

Thermal barrier coatings reduce the need for frequent maintenance by protecting engine components from wear and tear. As the coatings protect against heat damage, the likelihood of part failure decreases, minimizing the risks of operational downtime.

Fewer breakdowns lead to increased uptime and smoother operations, which is necessary for industries relying on uninterrupted engine performance. With longer maintenance intervals, companies can focus more on productivity rather than constantly addressing repairs, guaranteeing a more efficient workflow.

Enhance Performance And Corrosion Resistance With A&A Coatings

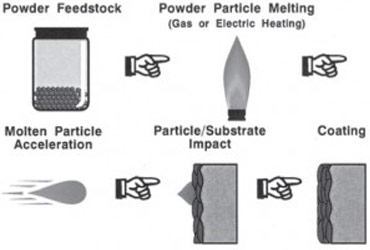

At A&A Coatings, we provide advanced thermal spray coatings that enhance the efficiency and performance of your machinery. Our thermal spray coatings improve heat resistance, allowing your engines to operate at higher temperatures with reduced risk of damage. These coatings are designed to protect critical components, guaranteeing better durability in extreme conditions.

We also bring innovative corrosion-resistant coatings that shield your equipment from wear and tear caused by harsh environments. Our corrosion-resistant coatings reduce maintenance needs and extend the lifespan of your machinery. Explore our solutions at A&A Coatings and discover how we can meet your specific industry requirements. Contact us today.