A Deep Dive Into Conformal Coating Inspection Processes

Conformal coating inspection is needed to guarantee the reliability and functionality of electronic assemblies. This process involves a detailed examination to detect defects like conformal coating errors and make sure of uniform coverage and appropriate conformal coating thickness.

Knowing the intricacies of conformal coating inspection processes is necessary for maintaining high-quality standards in electronics manufacturing.

The Importance of Conformal Coating Inspection

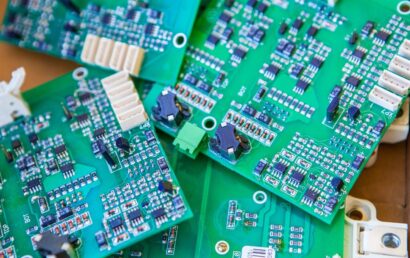

Conformal coatings cover electronic circuit boards to protect them from moisture, dust, chemicals, and other environmental contaminants. But for these coatings to safeguard the electronics, they must have uniform application and be free of defects.

Conformal coating inspection plays a big part in adherence to quality standards and specifications. By identifying problems like uneven coating thickness, bubbles, cracks, or incomplete coverage, inspection helps to make sure the electronics meet reliability requirements.

Methods and Techniques Used in Inspection

Several methods are used during coating inspection to assess the quality and integrity of the coatings. Visual inspection remains a basic technique, involving trained inspectors examining boards under magnification to detect defects.

Automated optical inspection (AOI) systems use cameras and software algorithms to analyze coated boards for defects rapidly and with high accuracy. AOI can detect issues like insufficient coating, voids, or inconsistencies in thickness that may not be visible to the naked eye.

What’s more, fluorescence inspection uses UV light to identify areas where the conformal coating may be missing or improperly applied. This method relies on the fluorescence properties of the coating material to highlight discrepancies that require further evaluation.

These inspection techniques are complemented by other testing methods, including solvent resistance tests and electrical testing, to provide for the coating’s functionality and durability.

Challenges and Considerations in Conformal Coating Inspection

Despite advances in inspection technology, challenges persist in achieving thorough and reliable assessments of conformal coatings. The complexity of electronic assemblies, with their intricate designs and components, can pose challenges for uniform coating application and inspection.

Things like component height variations, shadowing effects, and surface tension can affect coating uniformity and complicate inspection processes.

Attending to these challenges requires careful planning, calibration of inspection equipment, and continuous training of personnel to interpret inspection results accurately.

Industry Standards and Best Practices

To maintain consistency and quality in coating inspection, adherence to industry standards and best practices is imperative.

Standards like IPC-A-610 for electronics assembly and IPC-CC-830 for conformal coatings provide guidelines on acceptable levels of coating thickness, coverage, and defect limits.

Following these standards helps to make sure that electronic assemblies meet reliability requirements and perform effectively in their intended environments.

Precision Assurance: Advanced Conformal Coating Inspection

A&A Coatings knows the importance of conformal coating integrity in electronics and sensitive components. Our cutting-edge inspection process guarantees optimal protection and performance.

Using high-resolution optical systems and advanced UV inspection techniques, we carefully examine each coated surface for uniformity, thickness, and coverage.

Our expert technicians employ both automated and manual inspection methods to detect even the slightest imperfections, ensuring complete conformity to industry standards and client specifications.

This rigorous approach means that your conformal coatings provide maximum protection against moisture, dust, and chemical contaminants, extending the lifespan and reliability of your electronic assemblies.

Boost your product reliability with our expert conformal coating inspection services. Call 888-725-0150 or use our online form to reach out and learn more.