Advancements Made In Surface Protection For Medical Devices

Every day, throughout the world, advancements are being made in the medical profession. Surface protection for medical devices has been one of those advancements. And medical devices have become one of healthcare’s biggest markets. So, you can probably imagine the importance and significance of the surface treatments used on those devices.

Medical Devices

Today’s medical devices are used in the prevention, diagnosis, mitigation, and/or treatment of abnormal physical conditions and diseases. But the body, due to the unnatural materials from which these devices are made, offers up a natural resistance to them. These unnatural materials can consist of nitinol or solid steel core wires, latex rubber or silicone, and other nonbiological materials. Foreign materials being inserted into our bodies can cause discomfort and pain as well as raising the risk of infections, damage, other life-threatening ailments. Complications are a considerable concern among patients and healthcare professionals. To help minimize these complications, the medical device industry has wisely begun using hydrophobic and hydrophilic coating formulations.

Hydrophobic and Hydrophilic Coatings

These are the two types into which medical coatings have been segmented. Distinct deficiencies and applications differentiate each coating’s specific demands.

Hydrophilic technologies offer low friction performance. What that means in this application is that the navigation of a medical device through anatomical pathways is made easier by reducing patient discomfort, reducing tissue damage, and improving device control. When compared to a non-coated surface, these technologies can reduce friction by as much as 98%.

Hydrophilic coatings offer water retention and lubricity characteristics. In addition to reduced friction and offering the benefits just listed above, cost and procedure time have been reduced, and outcomes improved.

Hydrophobic coatings are used on devices such as instruments and surgical tools that would ordinarily become fouled with tissue debris or fluids. For longer periods of time, and in general, surgical tools can be kept cleaner. These coatings allow easy slide off of tissue and repel urine, blood, and other fluids. They offer anti-corrosive effects as well. All of these things together work to reduce infections and contamination in patients.

Coating Applications

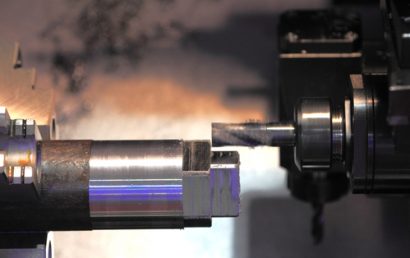

The applications are equally as important as the coatings. There are cons and pros to each method. Methods used are not necessarily applicable to all materials or devices. They are as follows:

- One common process for medical device coating is dip coating.

- When small intricate devices are not being coated, a reel to reel coating system might be used. This system is, however, for most devices, simply ineffective.

- When coatings are applied to a surface as a mist, using a nozzle and driver, the coating solution is applied through a spray coat system.

- Another common technique is referred to as spin coating, but this is a slow process and can only coat flat surfaces.

- Complicated shapes can be coated using robotics coating.

- And finally, though rare for most coating manufacturers, is submersion coating. It has the most efficacy and is easiest to apply.

When it comes to surface protection, be it on medical devices or some other substrate, A&A Coatings can provide the material and application needed. For decades, we have been doing just that for numerous industries throughout the nation. Our in-house capabilities are numerous, we offer coating specialization, and are dedicated to the needs of our customers. Contact us today to see how we can offer the most cost-effective solution to your industry’s surface protection needs.