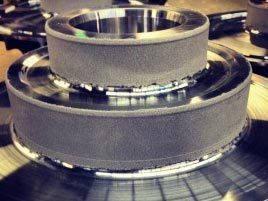

Abradable Coating

When we refer to the abradability of a coating, we are talking about its wear resistance in comparison to a more abrasive material that rubs against that coating. The main role of abradable coatings is to allow an automatic adjustment in clearance to accommodate thermal scenarios or physical interaction events when a device is operating.

A&A Coatings | Thermal Spraying Process to Achieve Abradability

Our plasma sprayed coatings such as aluminum-polyester and aluminum-graphite have been specifically developed to provide precision clearance control with the ideal balance of abradability and erosion resistance. The composite abradable thermal spray powders that we use are very high quality, thus ensuring that the coatings stay durable for the longest time possible. We often apply these types of coatings to typical machinery such as cryogenic radial expansion turbines, centrifugal compressors and gas turbine engines which are often featured in the aircraft jet engines.

Benefits of Abradable Coatings

Our thermal spray coating solutions are tailored for different industry needs and here’s a list of key advantages you can gain when you opt for abradable coatings from A&A Coatings:

- Excellent resistance to oxidation

- Good resistance to thermal shock

- Good resistance to impact

- Excellent internal strength

- High degree of abradability

- Low coefficient of friction

- Ideal balance of abradability and erosion resistance

- No blade or tip wear in contact with coating

Common Parts That Need Abradable Coatings

Our services can suit a wide variety of industrial applications but below are the most common parts that are coated with abradable materials:

- Shafts

- Drive collars

- Labyrinth seals

- Turbine wheels

- Compressor wheels

- Expander shrouds

- Compressor shrouds

- Expander wheels

- Compressor impellers

- Expander impellers

Since 1944, A&A Coatings has been providing customized thermal spraying solutions to help our clients achieve abradability for their products. Talk to us today if you want to learn more about our abradable coatings.