Conformal Coating Vs. Potting: Know The Difference

When looking to protect sensitive electronics, the choice between conformal coating and potting plays a significant role in their durability. These two methods are both effective, but they serve different purposes. Conformal coating offers a thin protective layer, while potting provides a complete encapsulation. This comparison clarifies how each option enhances the longevity and performance of electronics, ensuring they perform under harsh conditions.

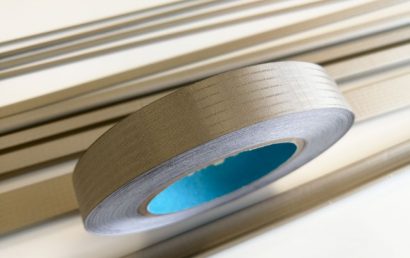

What Is Conformal Coating and Its Benefits

Conformal coating is a protective layer applied to electronic components to safeguard them from environmental factors like moisture, dust, and chemicals. The thin coating conforms to the surface of the components, forming a barrier without obstructing any delicate parts. The coating materials used can include acrylics, silicones, and polyurethanes. One of the key advantages is its ability to protect against corrosion, enhancing the longevity of components exposed to various elements. It also allows for heat dissipation, which helps prevent overheating of the components. Conformal coating is suitable for applications where components need protection but cannot be fully sealed.

What Is Potting and Its Key Benefits

Potting involves encasing electronic components in a solid or gel-like substance, usually a resin, to provide complete protection. This method fills the entire enclosure, effectively sealing the components from external elements. Unlike conformal coating, potting materials create a physical barrier, offering robust protection against moisture, chemicals, and physical shock. Potting can also reduce the risk of electrical shorts, as it insulates components completely. The primary benefit of potting is its ability to protect components from extreme conditions, making it ideal for harsh environments or high-risk applications. The encasement also contributes to heat dissipation, improving component reliability.

Key Differences Between Conformal Coating and Potting

The main difference between conformal coating and potting lies in the level of protection they provide. Conformal coating is a thin layer applied to the surface of components, offering flexibility and protection while maintaining accessibility to the parts. It allows for some degree of heat dissipation and is often used in more compact electronic designs. On the other hand, potting completely encapsulates the components, providing a much higher degree of protection against environmental factors and physical damage. Potting is often used for larger, rugged applications requiring complete sealing. Conformal coating works better for delicate or space-constrained environments.

Best Applications for Conformal Coating in Electronics

Conformal coating is ideal for protecting electronics in environments that are exposed to moderate levels of moisture, dust, or chemicals. It is commonly used in automotive electronics, circuit boards, and consumer electronics, where components must be shielded from potential damage without being fully sealed. For example, conformal coating is widely used in mobile phones, laptops, and automotive control units. It allows for protection against moisture and environmental contaminants, while also ensuring that the components remain accessible for maintenance or repairs. Its versatility makes it an excellent choice for a broad range of commercial and industrial applications.

Protect Your Electronics with the Right Coating Solution: Conformal Coating Vs. Potting

At A&A Coatings, we provide top-tier conformal coating services to protect your electronic components effectively. Conformal coating helps shield sensitive electronics from environmental risks, offering a thin yet durable layer that doesn’t obstruct vital functions. When you require more robust protection, we also offer potting materials for electronics, which fully encapsulate components to safeguard them against extreme conditions and potential damage. Reach out to us to Explore our advanced technologies at A&A Coatings today!