Corrosion Protection Coating For Wind Turbines: How Does It Work?

Corrosion protection coating is an important part of wind turbine maintenance. Not only will it help extend the life of your wind turbines, but it can also save you money in the long run. Corrosion protection coating works by sealing off any cracks or gaps in metal parts so that they cannot be used as an entrance point for moisture and oxygen. This prevents moisture from being absorbed into the metal itself, where it can cause rusting and corrosion. This article will explain how protection coating for wind turbines and why it’s so effective at keeping your wind turbine working properly for years to come.

Understanding Corrosion Protection Coatings for Wind Turbines

Corrosion is a natural process when metals react with oxygen, water, and other elements to form a protective layer on their surface. Over time, this layer can build up and form rust, which can cause great damage to your property.

Corrosion protection coating (CPC) is a substance that prevents corrosion and protects metal objects against weathering by acting as an invisible barrier between the metal surface and its environment. The type of CPC you choose will depend on what kind of exposure you expect it will face over time. For example, if you’re going to apply CPC to an object exposed directly to the rain or submerged in water (like boats), then choosing one with high-performance resistance against wet conditions might be wise. However, if the object has limited exposure outdoors but needs protection from UV rays, such as those found in many industrial settings, then choosing something designed specifically for UV protection may be more appropriate.

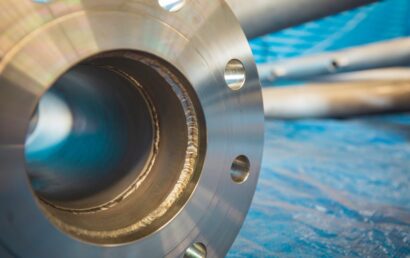

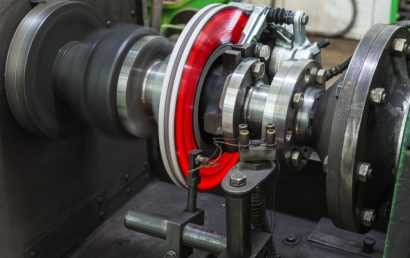

Wind Turbine Fittings And Corrosion Protection Coating

Wind turbine fittings are exposed to the elements. They are made of metal and, therefore, subject to corrosion. Corrosion protection coating is a thin layer of metal that protects wind turbine fittings from environmental effects, such as rain, snow, ice, and salt spray.

Corrosion protection coatings are typically applied by a spray-on method in one or two coats. The first coat should be applied when there is still some excess moisture on the surface of your equipment because this will help prevent pitting on your equipment during drying time (between coats). The second coat is usually buffed after about 24 hours have passed so that it can harden properly before being put into service again.

Corrosion protection coatings can be applied in powder form as well as liquid form depending upon what type of surface they need protecting most efficiently at any given time – either way, they are effective ways to keep things looking good while also keeping them protected against harmful conditions like water damage caused by weathering elements or other types of corrosion caused by exposure over long periods without proper maintenance.

Advantages Of Using Corrosion Protection Coating

There are many reasons why corrosion protection coatings should be applied to wind turbines.

- It protects the wind turbine. Wind turbines can be very expensive, so keeping them in good shape makes sense. The coating will protect the metal from corrosion and rust, ensuring that they don’t need to be replaced or repaired before its natural lifetime is up.

- It protects the environment. The process of making zinc oxide (the main ingredient in most corrosion protection coatings) produces pollution and greenhouse gases that contribute to climate change, but these emissions are reduced by using less energy during production and by recycling waste products into new materials at another facility next door (which reduces transportation costs).

- It protects workers who work on wind farms – if a worker falls onto something sharp because they didn’t realize there was no protective coating underneath a piece of metal, they could get hurt! Not only would this mean delays while everyone involved recovers but also additional costs associated with wages being paid out while someone is unable to do their job due to injury-both things which could have been avoided with proper precautions taken beforehand such as applying proper corrosive resistant coatings over areas like blades where people commonly come into contact with them during regular maintenance checks/inspections.