Diverse Applications Of Conductive Coating

In the expanding universe of modern technology, the importance of conductive coatings cannot be understated. These coatings play pivotal roles across a myriad of industries, providing not just conductivity but also protection against various environmental factors. Let us explore some prominent conductive coating applications across different sectors and understand their significance.

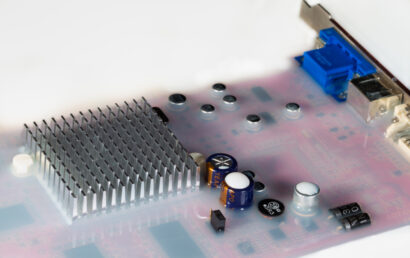

Electronics and Telecommunications

One of the primary applications of conductive coatings is in the field of electronics and telecommunications. These coatings shield electronic components from electromagnetic interference (EMI), ensuring devices function optimally without unwanted disruptions. Especially in densely packed electronic environments, a conductive layer acts as a barrier, preventing electromagnetic waves from affecting the device’s operations. Moreover, the coatings can protect components from electrostatic discharge, which can be detrimental to their functionality.

Automotive Industry

With the rise of electric vehicles (EVs) and the continuous integration of advanced electronic systems in modern cars, the automotive sector heavily relies on conductive coatings. These coatings, applied to vehicle components, help in managing EMI, ensuring that onboard electronics, including sensors, GPS, and infotainment systems, function without interference. Additionally, with cars being exposed to various environmental conditions, these coatings provide a protective barrier against corrosion, ensuring longevity.

Aerospace and Defense

In the aerospace and defense sectors, reliability is paramount. Aircraft and defense equipment house numerous electronic systems that need to operate flawlessly. Conductive coatings play an integral role in ensuring that these systems are shielded from both EMI and environmental factors. Given the critical nature of many aerospace missions and defense operations, a conductive coating helps ensure that devices and equipment function without fail, even in demanding conditions.

Medical Devices

The medical sector has witnessed rapid technological advancements, with devices becoming more sophisticated. These devices, especially implants like pacemakers, require conductive coatings to ensure they function correctly within the human body. The coatings not only provide the necessary conductivity but also offer a biocompatible barrier, essential for any device that interacts with human tissues.

Solar Panels

Solar panels, the harbingers of green energy, benefit immensely from conductive coatings. These coatings, typically applied to the surface of solar cells, aid in collecting the electric current generated when sunlight hits the panel. Given that these panels are exposed to the elements, the coatings also offer protection against corrosion, enhancing the lifespan of the solar cells.

Touchscreens and Displays

The screens we frequently touch, swipe, and tap on our smartphones, tablets, and other devices owe their functionality to conductive coatings. These coatings, often made from proprietary coatings materials, make the screens responsive to touch. They carry the electrical signal from the point of touch back to the device’s processor, allowing us to interact seamlessly with our devices.

Antistatic Flooring

In environments where static electricity can pose risks, such as in some manufacturing units or server rooms, antistatic flooring becomes crucial. A conductive coating, when applied to floors, ensures that any static electricity generated is grounded, safeguarding both equipment and individuals from potential static-related hazards.

From the device in your hand to the car you drive and even the solar panels powering homes, conductive coatings have a broad spectrum of applications, underscoring their importance in today’s technologically-driven world.

As industries evolve and the demand for reliable, efficient, and long-lasting electronic components grows, the role of conductive coatings is set to become even more pivotal. By understanding their diverse applications and ensuring their integration in coating processes, industries can ensure the durability, efficiency, and optimal performance of their products.