How Do Abradable Powder Coatings Improve Precision Devices?

Abradable powder coatings may also be referred to as AAPCs, or additive/abradable powder coatings. They can overcome tribological challenges in precision equipment, such as engines, by improving efficiency and fit with a dry film lubricant coating. Where ingested sand is a problem, component protection is also offered by these coatings.

Standard powder coating technology is used to apply AAPCs. They are utilized for lubrication, sealing, and clearance control over a wide range of temperatures in dry and oiled devices. The application of AAPCs is environmentally friendly and inexpensive.

How Are AAPCs Made?

Solid lubricants (such as graphite and epoxy) and thermoset resins are blended to create AAPCs. Because they can be applied thickly (per surface, 150 um or more), they are used frequently to bury operational wear-caused surface damage and to build up components. In specific applications, for maximum benefit, the tailoring of AAPC formulations can increase wear resistance, porosity, lubricity, and strength, selectively.

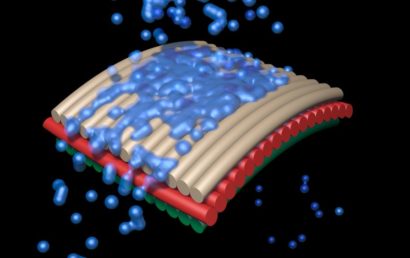

These coatings are made up of materials that will wear off, or abrade, when rubbed against a mating surface. When a surface comes into contact with another surface, these coatings act as a sacrificial layer protecting the base material underneath. It remains unharmed.

What Can AAPCs Do?

Abradable powder coatings can cut components’ fuel consumption and logistics, reduce sustainment costs, and improve readiness in industries such as the military. They coat parts in such a way that minimized friction and clearance are realized for the longest life, quietest operation, and highest efficiency of a component or surface.

Processing is effective, robust, and easy on both used and new components in remanufacturing, production, and prototyping. Components that are worn can be restored to performance levels that are easily classified as “better than new”. Applications include lip seal seats, refrigerant compressors, screw compressors, roots blowers, hydraulics, lube pumps, IC pistons, turbos, and others.

Between mating parts in precision machinery, AAPC safely promotes uniformly distributed contact and minimizes clearances. Additionally, when fit of mating components is optimized, wear, vibration, and noise are frequently reduced.

In aerospace turbine engines, a seal is provided between stationary and rotating parts thanks to recently developed abradable materials. The increased efficiency of blowers, engines, pumps, compressors, and more can be realized through the use of AAPCs.

AAPCs

The reason for the abradability of these coatings lies in their low structural integrity. When they come in contact with a moving surface that has a structural integrity that is higher than theirs, they readily abrade. To cater to different mating materials, corrosive environments, and operating temperatures, there are a number of different types of abradable coatings.

These coatings fall into two basic categories:

- Uniform and dense – These structured coatings have additives such as boron nitride, bentonite, graphite, and polymers. The additives provide a degree of dry lubrication and intentionally weaken the coating’s matrix material.

- Porous – These contain many un-melted or unreacted particles which help achieve the perfect abradability. Spraying parameters are carefully selected to produce these AAPCs. They need strict monitoring and can be hard to accurately reproduce.

A&A Coatings offers abradable powder coatings, protective coatings, resurfacing, and much more. Different types of coatings are used in different situations and industries, as well as various application methods and materials. If you have questions about what kind of coating would best serve your business or your industry, contact one of our knowledgeable service representatives today.