How To Restore The Surfaces Of Rotary Screw Compressors

Using precision machining, advanced metallurgy, and laser cladding technology, damaged and worn out rotors are now being remanufactured. So much so, in fact, that they’re better than brand-new! But first things first, what are rotary screw compressors?

These compressors are a kind of gas compressor that uses a positive displacement mechanism classified as a rotary type. With close-fitting rotors, this mechanism works in a sweeping, continuous motion. But, efficient and proper operation of a rotary screw compressor is dependent upon maintaining tight clearances between screws, bearing journals, and tips.

A Problem Arises

Used in a vast array of harsh environments, rotary screw compressors are efficient and simple machines. But, to prevent leakage and for efficient operation, maintaining snug clearances between bearing journals, screws, and tips is necessary. Poor air quality is present in any number of harsh environments in which rotary screw compressors work, and this accelerates component wear.

Environments such as that just referred to could (as an example) be mining and drilling sites where accelerated wear occurs and results in less than ideal air quality. Ordinarily, the solution that maintenance crews would turn to is to take a brand-new OEM assembly and replace the whole compressor rotor module.

And unfortunately, if a new part is mishandled, additional damage will only add to the inefficiency already threatened by harsh operating conditions and poor air quality.

A Solution Is Born

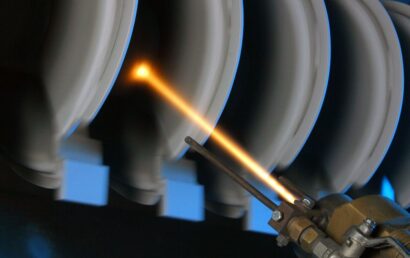

Using laser cladding, bearing journals and worn fine edges can now be rebuilt. Using material precisely matched and successive passes of the laser, damaged rotor parts can be rebuilt. After the rebuilding process, rotor parts are sent to machine workshops and reground. This way, original OEM clearance specifications can be restored.

Why does the laser cladding process have unique benefits? This is because of the ability to metallurgically bond the substrate and a superior wear surface. On tips, a different cladding material is used to provide high erosion wear resistance. High erosion can occur when, in a high velocity air stream, super fine particulate matter exists.

For applications that take place in less than desirable air quality conditions, the above stated process provides a longer service life.

Specific Benefits Which Can Be Achieved

Using a laser cladding process offers multiple benefits. Some of these are as follows:

- Low carbon footprint and less waste which results in a better outcome for the environment.

- Superior life is offered by remanufactured screw components.

- When compared to the cost of replacement parts, huge cost savings.

- Full restoration of the worn compressor’s operating efficiency.

- The recovery of damaged rotors so they can be put back into normal service.

Bottom line: At a fraction of the cost, laser bond cladding saves parts from being scrapped and makes them good as (or better than) new. A&A Coatings has been involved in the refurbishing and rebuilding of parts for decades. With the right coating, maintenance and part replacement costs can be slashed considerably.

If you would like to find out what kind of coatings best suit the needs of your company and your industry, contact one of our knowledgeable specialists today. At A&A Coatings, we want to help you improve your bottom line!