Improve Your Bottom Line With The Right Marine Coatings

Protective marine coatings – meant to guard surfaces from harsh environments – differ from other coatings in a very significant way. They are expected to stand up to salt in the air and in the water, as well as certain chemicals. Their utilization by companies that rely on repeated use of equipment, parts, etc. is crucial. They must be able to avoid replacing equipment, parts, and more, too soon and/or too often. Additionally, not only machinery but also containers (tanks) must be ready to go at a moment’s notice in order for companies to enjoy an impressive bottom line.

Where cargo containers are concerned, it is imperative that between cargoes, crews can move quickly. The time needed to switch from one car go to another can be reduced, and the range of cargoes extended, if the right coating is selected.

ROI, Versatility, and Cleaning Requirements for Marine Coatings

Lower maintenance costs are more easily achieved using properly coated tanks because they have a longer service life. So, not only will companies be able to use the tanks longer, they may be able to save money on their initial construction compared to that of a stainless-steel tank. Construction of a stainless-steel tank can, in fact, cost somewhere around three times as much as a specially coated tank of a different material.

There are other drawbacks to stainless steel in addition to its price tag. Cleaning can be costly due to constant problems with chloride attack. Initially, tanks are washed out with sea water – to remove certain cargo residues – at specific temperatures. If possible, to remove chlorides, washing with fresh water is then done. Only freshwater is used on some cargoes.

At various points throughout the life cycle of a cargo tank, stainless-steel tanks require passivation in order to maintain a specific quality. The specific cargo carried can determine passivation. Over the lifetime of a ship, devoted to maintaining tanks is approximately 16% of the entire maintenance budget for a stainless-steel tanker. Whereas 16% might not seem like much to some people, it is a giant chunk being taken out of a company’s bottom line.

Phenolic Epoxy Coatings

With high absorption properties, phenolic epoxy coatings – when it comes to cargo loading and cleaning – have high restrictions. When sensitive chemicals such as edible oils are carried, there are strong cargo restrictions in place. Following the carriage of aggressive water-soluble cargoes, no aqueous cargoes, slops, wash water, ballast water, or steam may encounter the coating prior to its condition being restored. Restoration is achieved through ventilation.

Zinc Coated Tanks

Sometimes, tanks for the purposes mentioned here are zinc-coated for protection. Let’s say you have one of these a zinc-coated tanks and you’re using it for cargo.

Let’s further say that you had a cargo that consisted of vegetable oil, gas oil, or dyed gasoline. Now, however, you need to switch your cargo to MEG or methanol. Naturally, you’re going to want to clean out that tank. But beware! Zinc can be destroyed if traditional cleaning chemicals are used because of the vegetable oil, gas oil, or dyed gasoline you already transported in this tank.

You should only use chemicals that have been deemed safe for cleaning zinc. Into the capillaries and pores of the tank and its coating, previously carried cargo can migrate because tanks coated with zinc silicate are inherently porous.

Turn To A&A Coatings for your Marine Coatings

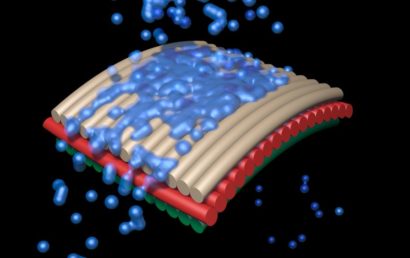

With HVOF, plasma spray, or any one of the other coating processes available through A&A Coatings’ thermal spray applications, ceramics, tungsten carbide, and other materials can be used for marine coatings. Corrosion resistance, wear resistance, and more are offered by these protective coatings.

If you’d like to find out how our coatings can help improve your bottom line, contact one of our knowledge representatives today.