Industrial Plasma Spray Coatings Explained

Among industrial manufacturers, a common choice today is industrial plasma spray coatings. This is particularly applicable when, to distribute a feedstock (molten material) onto a substrate (surface) a 15,000°C plasma jet is used. Granted, there are numerous methods of thermal spraying. But, possibly the most versatile among them is plasma coating. A large number of coating materials can be applied thanks to the extremely high temperature used.

Why thermal spray with plasma coatings? On structural materials, it helps to prevent wear and corrosion. Typically, additional resistance to heat, abrasion, cavitation, and erosion are specifically protected against with the right kind of coating. What’s more, it can be used for aesthetic purposes, or cleaning surfaces, as well as to create etchings.

Materials Used

During the plasma spray process, in either wire or powder form, many feedstock materials are usable. Materials possessing a high melting point can be melted with plasma: i.e., zirconium, ceramics, tungsten, etc. Because it would not be hot enough, this could not be achieved with normal combustion.

The result of the materials used could be the following:

- Protection against the elements

- Reduced conductivity

- Water resistance

- … and more

The Process

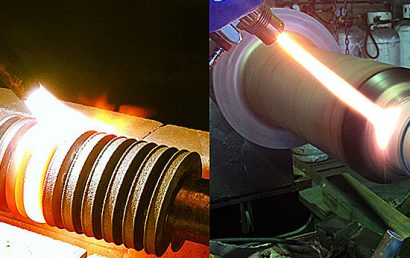

To heat a feedstock material, plasma is used after the gas, necessary for the process, has been heated. The feedstock melts as it’s fed into the path of the plasma. Then, sprayed onto the surface of a substrate, the resulting droplets create the desired plasma coating. The term “lamellae” is used to describe these droplets. These rapidly cool as they flatten onto the substrate to form a thin top layer.

Feedstock material, after cooling, remains attached to the substrate. It can be removed, in some cases, and then retained for use in another structure as a component.

Plasma Spray Guns

The guns used in plasma spray are created from high-quality cathodes and anodes, negatively and positively charged. Toward the anode, and around the cathode, plasma gases such as hydrogen or argon flow. Between these points, a DC arc forms via the high-voltage discharge. This creates plasma as the gas is heated to extreme temperatures.

Then, out of the gun’s end nozzle, the plasma is directed down and out. In the plasma coating process, it is at this stage that the gun is ready to use. The plasma spray gun is water cooled to prevent issues with overheating.

Plasma Spraying – Common Applications

Plasma sprayed coatings are typically used in the following applications:

- For dental and medical implants, hydroxyapatite coatings which are biocompatible.

- Diesel engine piston rings application of molybdenum alloys.

- For subsequent diamond and laser etching/engraving, wear resistant chromium oxide ceramic and alumina on printing rolls.

- On turbine combustion chambers, zirconia based TBCs (thermal barrier coatings).

- To resist fretting wear, used to seal ring grooves (this application refers to tungsten carbide/cobalt aero engine turbines’ compressors).

Where plasma sprayed coatings are concerned, some examples of industry sectors using it today are as follows:

- Electronics

- Household appliances

- Glass, steel, and iron wear

- Nuclear industries and chemicals

- Biomedical

- Automotive engineering

- Marine engineering

- Mechanical engineering

- Aerospace

Contact us at A&A Coatings today if you would like to find out how plasma coatings are already being used in your industry, and how your specific business can benefit from the use of them.