Do You Need Anti-Slip Coatings?

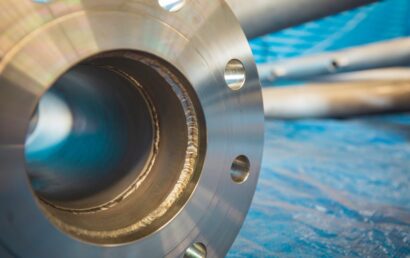

When it comes to industrial machinery and equipment, one of the most noticeable and major properties involved is the need for non-skid and anti-slip surfaces. This is where thermal coatings come in. They can be custom engineered to act as non-skid and anti-slip coatings.

Anti-Slip Surface Coatings

If you need a surface to grip with visible feed application, a thermal spray applied to the surface could be the answer. Specific surface traction can be imparted on a surface through thermal spray coatings. There are a number of processes that can be used in order to create the level of anti-slip properties that are desired. These processes include the following (among others):

- Metalizing

- Arc Spray

- Plasma Spray

- HVOF

Achieving An Anti-Slip Surface Through Thermal Spray Processes

In order to achieve a specific anti-slip level in components, various processes are used. These processes can include the following:

- Flame spray– Essentially, the same process as wire arc (see below) is used here except that no extension nozzle is used. This means that a wider surface can be covered by the applied coating. This is not a precision application. Another type of flame spray is powder spray, which can also be used to apply component surface anti-slip coatings.

- Wire arc process a.k.a. electric arc– Here, between tow wires a charge is placed. This raises the temperature to a specified point. These temperatures, through an extension nozzle, are accelerated and that is how the application of coating to specific components or parts is executed. This can be a very precision application.

Why Use Anti-Slip Coatings?

The answer here is easy – whether your purposes are industrial, household, or commercial, you want the best suited end surface possible. Thanks to the various choices of materials which can be used for this process, one or more coatings can be applied to achieve the perfect end result. And this is not a temporary fix. It is far more long-lasting and tougher than temporary fixes like glues or paper wraps. Following a long and useful application, should the anti-slip surface eventually wear away, your thermal spray company will simply strip off the old coating and recoat as needed.

What Kinds of Parts Would Require Anti-Slip Coatings?

Any number of applications can make good use of anti-slip coatings. However, these coatings are commonly applied to the following (among others):

- Winter Drums and Instruments

- Reels

- Tool Surfaces

- Traction Rollers

- Carpet Rollers

- Grip Fingers

- Friction Discs

- Freed Rollers

- Texturing Roll Surfaces

- Fiber and Textile Parts

In industrial sectors, applications for these coatings can be as follows:

- Material Handling Industries

- Petro Chemical

- Automotive

For over 70 years, A&A Coatings has been servicing and satisfying a diverse selection of clientele. We can supply the required non-slip coatings applied through our wide range of thermal coating processes, to a sure your company the best anti-slip surfaces available. If you would like to know more about anti-slip surface coating and its many applications, contact A&A Coatings today.