Spray And Diffuse Hardfacing Can Help Strengthen Metal Parts

Metallic parts are manufactured to withstand certain levels of stress. However, even at lower stress levels, sometimes metal parts can fail during the use for which they were intended. This can be caused by wear. There are numerous types of wear including the following: corrosion, heat, metal to metal contact, impact, and abrasion. The strength of metal pieces can be severely compromised by all of the above. Spray and diffuse hardfacing is a technique which, when applied to a component or surface, can prolong the life of metal pieces and help lessen the types of wear just mentioned.

An Explanation of Spray and Diffuse Hardfacing

Also referred to as hard surfacing, hardfacing uses welding with which to provide a wear resistant metal by covering a metallic part. Hardfacing is commonly needed by certain alloys which can include those which have a less than 1% carbon content. In addition to low alloy steels this also includes stainless steels.

Hardfacing can be applied to pieces that are currently in use to extend their life and strengthen them. In order to prevent deterioration, to newly manufactured pieces, hardfacing can also be applied.

Costs

Here is a summarization of cost variations:

- 5 to 10 pounds per hour – OFW (oxy fuel welding)

- 5 to 12 pounds per hour – GMAW (gas metal arc welding), including both open arc and gas shielded welding

- 3 to 5 pounds per hour – SMAW (shielded metal arc welding)

- 8 to 25 pounds per hour – FCAW (flux cored arc welding)

Materials

Cobalt-based alloys are the most commonly included applied materials: i.e., chromium carbide alloys and other nickel-based materials, and also stelite.

Providing better overall resistance to abrasion, more advanced materials can be used: i.e., vanadium, tungsten, molybdenum, and columbium. They are good for situations involving abrasion at a severe level because they have low friction factors.

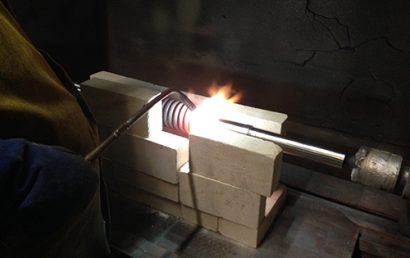

Techniques

The relative hardfacing method cost and a part’s geometry help to determine the proper hardfacing technique for a particular project or job. Along with the deposition rate of a material, costs may vary.

Sometimes, to add instructional information, color, or to refinish a part, hot stamping may follow hardfacing. For added protection or a metallic look, films and foils can be added.

Methods of Welding

To provide wear resistance, there is a welding electrode for each industrial wear phenomena and application. By the following various welding methods, hardfacing can be deposited:

- Laser cladding

- Cold polymer compounds

- Thermal spraying

- PTAW (plasma transferred arc welding)

- ESW (electroslag welding)

- SAW (submerged arc welding)

- OFW (oxyfuel welding)

- GMAW (gas metal arc welding) which includes open arc and gas shielded welding

- SMAW (shielded metal arc welding)

A&A Coatings For Spray and Diffuse Hardfacing

Do you think that your company could benefit from hardfacing? Chances are, your industry is already using some type of thermal sprayed coating. Hardfacing is, of course, only one method of protection offered by the services we provide at A&A Coatings.

To improve your bottom line by lessening downtimes and decreasing maintenance costs, our coatings are invaluable. There are simply no two ways about it! Contact us today if you’d like to discover what hardfacing or another one of our thermal spray coatings can do for you and your business.