Transforming Surfaces: Ensuring High Standards With Thermal Spray Coating Services

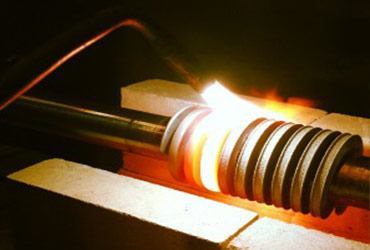

In industrial manufacturing, thermal spray coating services stand as a cornerstone of innovation and reliability. This technology isn’t just about covering a surface; it’s a transformative process that significantly enhances the properties of the coated material. Whether it’s resisting corrosion, enduring high temperatures, or combating wear and tear, thermal spray coatings bring a new dimension of durability and efficiency to industrial components. By embracing this advanced coating technology, manufacturers can not only extend the lifespan of their products but also improve performance, ensuring they meet the highest standards of quality and resilience in challenging environments.

A&A Coatings: Your Partner in Surface Transformation

At A&A Coatings, we specialize in elevating the standards of industrial surfaces through our bespoke thermal spray coating services. Our facility is uniquely dedicated to the application of Metal, Ceramic, Cermet, and Hardfaced Coatings. We don’t just apply coatings; we engineer solutions tailored to the specific needs of your business. Whether you require enhanced wear resistance, thermal barrier protection, or corrosion resistance, our team of experts works closely with you to identify and apply the optimal coating solution. By choosing A&A Coatings, you’re not just getting a service; you’re gaining a strategic partner committed to enhancing the performance and longevity of your products.

Pre-Coating Surface Preparation Techniques

Pre-coating surface preparation techniques are fundamental to ensuring the effectiveness and longevity of thermal spray coatings. Before any coating is applied, it is imperative to prepare the substrate adequately. This involves a series of meticulous steps, starting with a thorough cleaning to remove contaminants like oil, grease, rust, and old coatings. Following cleaning, grit blasting is often employed to create a surface profile that promotes adhesion. This mechanical abrasion removes remaining contaminants and roughens the surface to provide an ideal anchor for the thermal spray coating. Proper surface preparation ensures the coating adheres securely to the substrate, minimizing the risk of delamination or premature failure.

Material Selection for Different Applications

Selecting the appropriate material for thermal spray coatings is a critical decision that directly impacts the success of the coating in its intended application. Thermal spray coatings are available in various materials, including ceramics, metals, and polymers, each with unique properties and advantages.

Ceramic coatings like alumina or chromium oxide are often chosen for applications where wear resistance is paramount. These coatings provide exceptional hardness and abrasion resistance, making them ideal for components subjected to abrasive wear or erosive environments.

When corrosion protection is a primary concern, metallic coatings such as zinc or aluminum are commonly selected. These coatings offer excellent corrosion resistance and are often used to protect steel structures and components from rust and degradation.

Ceramic coatings like zirconia or titania are preferred for applications requiring thermal insulation or electrical insulation. These coatings provide insulation properties and can withstand high temperatures without degrading.

Advantages of A&A Coatings in Surface Enhancement

The advantages of thermal spray coatings in surface enhancement are multifaceted, making them a preferred choice for industrial manufacturers and businesses. One of the most significant advantages is their ability to provide exceptional protection against wear and corrosion. Thermal spray coatings can significantly extend the lifespan of components and equipment exposed to harsh operating conditions.

Experience the A&A Coatings Difference

Ready to transform your industrial products with top-tier thermal spray coating services? A&A Coatings is here to deliver. Our exclusive focus on Metal, Ceramic, Plasma, Cermet, and Hardfaced Coatings ensures that your equipment receives the best protection and performance enhancement. Don’t settle for standard; boost your industrial components with coatings that are engineered to last. Contact A&A Coatings today and get on a journey towards enhanced durability, efficiency, and excellence.