Understanding Industrial Guardrails

In any number of industrial structures, as an integral part involved in providing barriers and safety, guardrails can be found. They can be incorporated into mezzanine structures, warehouses, and industrial sites and are typically found as platform-end installations. Guardrails are used in production areas, to prevent falls, and as protection barriers against vehicle impact on highways.

Fabrication materials used in standard guardrail composition include stainless steel variations. This material, due to its durability, is frequently recommended. Another common barrier material that isoften used in guardrails is wood. Guardrails come in numerous variations but all should comply with the standards set forth by OSHA. Standard guardrail installation options can include both double railing and single railing systems.

Applications for Standard Guardrails

The following are a handful of applications in which you will find guardrails being used:

- To minimize or prevent accidents, installed along roadways

- To protect doors, walls, etc. from damage, installed in buildings

- To protect forklift and other equipment against damage, installed in industrial settings

- As a barrier in transformer and workstation areas

- Installed as protection in pedestrian walkways

Various types of guardrails can include drop-in, bolt-on, curved, and W-beam.

The Components That Make Up Guardrails

Guardrails are not highly complex in their makeup but do utilize specific components. Some of the components most commonly found in guardrails and their makeup are listed here:

- Anchor bolts fasten base plates to the floor which is responsible for the standard mounting of a guardrail system.

- Frequently fabricated from steel, columnsare also included in many guardrail systems. They can also be referred to as posts, include installation hardware, and are frequently pre-drilled in manufacturing.

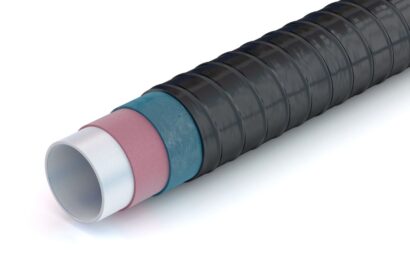

- For traffic areas, fabricated in 90°, curved variations, durability is provided by 12-gauge standard galvanized steel systems. Variations of this can include flatter beams which feature ribbing or cylindrical steel beams.

- OSHA yellow is often painted on railings used in many outdoor/indoor areas.

- Depending on application requirements, the amount and type of beam railings used varies. As an example: beams may have UV resistant polyurethane coated sleeves and/or can consist of anywhere from three beams to one beam.

Styles and Types of Guard Rails

Though the manufacturer usually includes the hardware needed for this type of railing, bolt-on rails involve specific drills, tools, and installation. Application selections can be triple rail, double rail, and single rail.

The drop-in rail is an easily accessible railing. They feature brackets which, upon installation, allow post sections to slip easily into the structure.

Constructed in high gauge steel, W-beams are the standard rails used in highway and traffic safety guardrails. Coated, weather resistant materials are used as well as the beams themselves being fabricated with zinc coatings. This is in the interest of protecting against conditions which could be considered environmental.

All Things OSHA

If they are not installed properly, guardrails can malfunction. So, for installation and worker safety reasons, OSHA standards should always be complied with. During installation, as an example, safety nets should always be utilized. More standard safety guidelines put forth by OSHA can be found on their website.

Why Use A&A Coatings To Protect Your Industrial Guardrails?

Our protective coatings are custom-made and tailored to your specific needs. A&A Coatings has been at the forefront of the industry for over 70 years and is devoted to the application of hard-faced, cermet, ceramic, and metal coatings. We can apply the appropriate coating needed to protect your industrial guardrails against wear and tear.

Contact us to see how A&A Coatings be of assistance in applying protective coatings to your choice of guard rail.