Understanding Metal Alloy Coatings

How well do you understand metal alloy coatings? If this type of coating is something new to you, fret not, as we are going to shed some light on the metal alloy variations. For starters, you should note that metal alloy coatings can be utilized as bonds for thermal spray coatings. In addition, the natural characteristics of the coating make it suitable for restoring dimensions of parts as well as improve resistance to corrosion and wear. When there is dimensional buildup of parts, there will be ease of machining. All in all, metal alloy coatings work well to protect parts from sliding wear and high temperature wear damage.

Common Types of Metal Alloy Coatings

At A&A Coatings, we have many years of experience working with and creating a wide range of metal alloy coatings. For a quick reference, below is a quick look at the most common types of metal based coatings:

- Zinc

- Bronze

- Stainless Steel

- Titanium

- Nichrome

- Nickel-Aluminum

- … and more!

Nickel-Aluminum Coatings

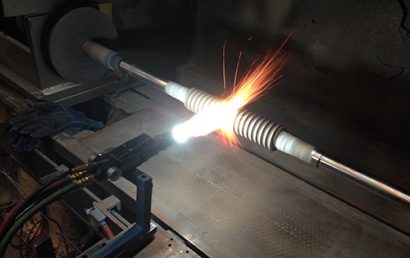

Nickel aluminum coatings are often industrial grade and is a solid wire that’s specially designed for arc spray systems. The great thing about these coatings is that it requires minimal surface preparation and is amazingly self-bonding to most materials. What’s more, the wire exhibits good resistance to both bending and impact. Since the coating is a one-step build up material for restoring dimensions, it will be a stellar idea to utilize as it as a bond coat for subsequent thermal sprayed topcoats.

Stainless Steel Coatings

If the application process goes smoothly, stainless steel wire will form a dense and well-bonded coating that provides exceptional wear resistance. Stainless steel coatings are also best used in arc spray processes, for enhancing part wear resistance, dimensional restoration and even machine element repair. Did you know that your stainless steel ‘friends’ also possess low shrink rate characteristics? Yes! And that’s why it allows for increased coating thickness on parts that require heavier industrial coatings.

Nickel-Iron-Aluminum Coatings

If you want to produce machinable stainless type industrial coatings, you should definitely opt for aluminum, molybdenum, nickel chromium powder. Nickel-iron-aluminum coatings have excellent corrosion resistance and good wear properties, allowing it to excel in hard bearing applications. As it is also possible to create high strength and low shrink coatings with these materials, they are highly recommended for applications that require resistance to particle erosion, cavitation, fretting and abrasive wear. Let’s not forget that nickel-iron-aluminum coatings are also perfect for the buildup and salvage of machinable carbon steels and machinable corrosion resistant steels.

Aluminum-Bronze Coatings

Industrial coatings that are developed from materials like bronze and aluminum are in fact an inert gas atomized powder. Aluminum combined with bronze can help enhance the corrosion resistance of thermal spray coatings and they are golden in color! What’s more, they are easy to machine and that’s why achieving excellent finishes will be a breeze. By forming a thin tenacious surface oxide on copper-rich alloy, the protective layer can enhance a part’s resistance galling and fretting at low to moderate temperatures. Require coatings for soft bearing applications? Aluminum-bronze coatings are the answer!