Understanding The Unique Characteristics Of Tungsten Carbide

Tungsten carbide has many uses which span a vast array of industries. In petroleum, mining, and metalworking industries, it is a compound of the utmost importance. Tungsten is contained in alloys used in high-speed tools manufactured with stellite, cristite, high-speed steel, and more.

Tungsten Carbide – Its Uses

Cutting is one of the main uses for tungsten carbide. The reason being that it is exceptionally tough and scratch resistant. So, for cutting work and the tools involved, one of the most extensively used products is tungsten carbide. In fact, better than steel tools, a sharper cutting edge is maintained longer when carbide tools are utilized. Faster machining is provided by their temperature resistance and on parts, they often produce a better finish than steel tools.

This is not to say, however, that cutting is its only use.

In cathode ray tubes and lightbulbs, tungsten carbide can be used as filaments. It is also used in field emitters, heating elements, and electrodes.

What Makes Tungsten Carbide Unique?

One of the attractive qualities of tungsten is its unique melting point. Compared to other metals, it’s melting point is the highest. Used in steel and other alloys, it imparts great strength. The high melting point makes it perfect for the above-mentioned lightbulbs and filaments but also arc-welding electrodes and electric contacts.

As far as the chemical properties of tungsten are concerned, several minerals come into play. The most essential of these are wolframite and scheelite.

What’s the Difference Between Tungsten and Tungsten Carbide?

Possibly the most important and biggest difference makes reference to the individual metal. Predominantly carbon, and an alloy of tungsten, tungsten carbide can also contain titanium and nickel, as well as other metals.

The two can be used interchangeably in any number of industries including the jewelry industry and are frequently used in place of one another in general. The jewelry industry prefers tungsten, particularly in the manufacturing of rings, because it does not rust, develop patina, or tarnish. For instance, over time, sterling silver rings need polishing because they tarnish. Compared to other types of metals used in jewelry, tungsten rings, etc. are extremely low maintenance.

Beware of Imposters

Tungsten carbide, because of its many desirable qualities, is sometimes copied. It’s important to be aware of imposters. The following are characteristics of tungsten carbide that fakes and knockoffs may lack:

- Difficult to bend, reshape, or resize (as in a jewelry application)

- High durability

- Scratch resistant

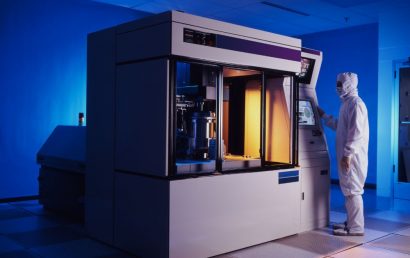

Tungsten Carbide As A Thermal Spray Coating

A&A Coatings uses tungsten carbide as a coating which can be exceedingly utilitarian in any number of industries and applications. For wear resistance, it is one of the most widely used protective coatings. We use a thermal spray process to apply our tungsten carbide powder mixed with a binder material.

Frequently, paper mills, metal and steel production, and power generation industries all utilize our tungsten carbide protective coatings in one capacity or another. If you require specific surface finishes, our experts can apply tungsten carbide coatings to a precise, particular finish as needed. Best of all, they will finish your project with the utmost speed and skill, providing you with an end result that is high quality and highly desired.

Talk to one of our knowledgeable representatives today to inquire about tungsten carbide and its renowned durability. See what thermal spray coatings can do for your bottom line.