What Factors Contributed To The Need For A Conductive Coating

Conductive coatings have been around for a long time, but nowadays, conductive coatings are typically used for EMI shielding, allowing plastic materials to make more of a presence in product design. Due to the non-conductive nature of plastic, incorporating conductive coatings has become an important technique for providing EMI shielding in digital electronic products manufactured with plastic casings. Read on to find out everything you will need to know about conductive coatings and when you should consider reaching out for a conductive coating on your appliances.

What is Conductive Coating?

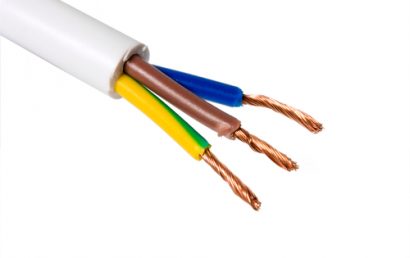

Conductive coating is a type of coating that can conduct electricity. These coatings allow electric currents to run through the surfaces of non-conductive materials such as plastic. Depending on how it is applied, conductive coating can be used in circuitry. A draw of conductive coating is its ability to allow us to use non-conductive materials in electronics, broadening the types of materials available for utilization.

What Type of Material is Used for Conductive Coating?

There are different types of conductive coatings, and depending on the application, you choose from graphite, silver, gold and nickel. A&A offers molybdenum, silver, copper, aluminum, and even blends of materials and alloys in order to provide different levels of conductivity.

What are the Benefits of Conductive Coatings?

Conductive coating is incredibly versatile and can be applied to basically any material or substrate. This type of coating is typically applied to non-conductive substrates such as plastics, polycarbonates, ceramics, or composites, imparting conductive properties to these dielectric components. It can be utilized to make circuits or as a form of shielding, It is also used to create printed capacitive sensors. In other words, conductive coatings will save you the trouble of seeking out expensive conductive materials for your component.

When Do You Need Conductive Coatings?

If you are looking to create heating elements, slip rings, in-situ thermocouples, static dissipative elements, flexible circuits, contact points, commutator segments, ground straps, and more. For any component that requires conductivity, you can consider applying a conductive coat. As stated, these types of coats can be applied to a variety of substrates so it comes down to your needs.

Thermal Spray Conductive Coatings at A&A Coatings

A&A Coatings is a surface engineering firm that provides industry-specific coating solutions. Our engineers utilize the thermal spray process to apply conductive coatings to enhance the conductivity of different types of substrates in industrial equipment. Most commonly, we will protect the sensitive areas from the coating process before grit blasting the other areas in order to make the surfaces rougher and ideal for chemical bonding. Lastly, the conductive coating will be sprayed on. Through the masking technique we use, we are able to control which areas are sprayed with conductive coating, allowing us to create patterns in the substrate to suit your needs.