What To Expect From Metal Coating On Ceramic Surfaces

Industrial processes often push equipment to extreme limits. This exposes surfaces to high temperatures, corrosion, and wear. The innovative metal ceramic coating provides a revolutionary solution to these challenges by combining the resilience of metals with the versatility of ceramics.

This coating not only enhances the durability and functionality of surfaces but also significantly extends equipment lifespan. Here is how this coating technology benefits industrial applications and optimizes equipment longevity.

Enhanced Durability and Strength with Metal Coating

Metal ceramic coatings create a barrier that improves the structural integrity of surfaces. Forming a robust layer, these coatings reduce the risk of damage caused by mechanical stress, abrasions, or high-impact forces. Industrial manufacturers depend on this technology to protect equipment from premature failure in demanding environments.

This enhancement makes sure that surfaces withstand prolonged use in harsh conditions without degrading. The aerospace and automotive sectors benefit significantly. Their equipment frequently endures extreme stress. These coatings help achieve longer operational lifespans. This guarantees equipment remains reliable under challenging circumstances.

Improved Thermal and Electrical Conductivity Benefits

Metal ceramic coatings elevate thermal and electrical performance across a wide range of industrial applications. Their exceptional thermal conductivity allows the equipment to distribute heat more efficiently. This will reduce the risk of overheating or thermal damage. This feature is critical for components in turbines, engines, and high-temperature systems.

In addition to thermal conductivity, these coatings offer excellent electrical conductivity. They improve performance in electrical systems by facilitating efficient energy transfer. Sectors like manufacturing and energy rely on this advancement to optimize equipment performance while reducing energy loss and operational inefficiencies.

Resistance Against Wear, Corrosion, and Oxidation

Surfaces treated with metal ceramic coatings resist degradation caused by wear, corrosion, and oxidation. These coatings form a protective layer that prevents direct exposure to abrasive materials or harsh chemical environments. They are invaluable for sectors like energy production and chemical processing.

This resistance minimizes maintenance requirements and makes sure that equipment stays operational for extended periods. By safeguarding surfaces against oxidation and chemical interactions, metal ceramic coatings allow industrial systems to maintain peak performance, even in highly reactive or moisture-laden environments.

Surface Finish and Aesthetic Transformation Results

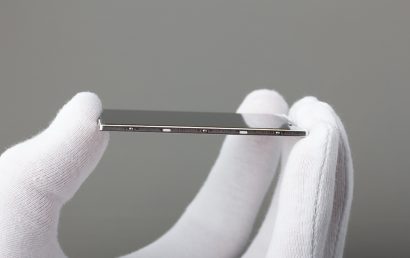

Metal ceramic coatings provide more than just functional benefits; they also enhance surface appearance. With smooth and uniform finishes, these coatings improve the overall aesthetics of equipment. This will add a polished and professional look to industrial components.

The transformation achieves not only cosmetic appeal but also improved performance. Smooth surfaces reduce friction and resist dirt accumulation. As a result, it becomes easier to clean and maintain. This combination of aesthetics and functionality makes metal-ceramic coatings a preferred choice for high-performance industries.

Customization Options and Coating Process Specifics

Customization is a defining feature of metal-ceramic coatings. This allows manufacturers to tailor solutions based on specific operational needs. The coating process includes thermal spraying, plasma coating, or chemical vapor deposition, each chosen based on the desired result and the substrate material.

These versatile coatings adapt to different thicknesses, finishes, and chemical properties. They are suitable for a variety of applications. Industries benefit from this adaptability by receiving optimized solutions that address precise challenges. The result is a coating process that delivers both consistency and efficiency. This will improve operational outcomes across diverse sectors.

Transform With Advanced Ceramic Coatings and A&A Coatings

Explore the advanced potential of advanced ceramic coatings. Discover how A&A Coatings redefines surface performance. Our innovative solutions strengthen surfaces – guaranteeing improved durability and thermal management for critical components. These coatings withstand intense operating environments. They are indispensable for industrial success.

As chemical-resistant coating specialists, we tailor our technologies to resist wear, corrosion, and chemical exposure. Our coatings extend equipment lifespans while maintaining optimal functionality. At A&A Coatings, we deliver precision, quality, and cutting-edge processes to enhance your operations.

Contact us today to protect and transform your equipment with our specialized coatings.