What You Need To Know About AMS 2451C

If you are in the surface finishing or brush plating business, you may have heard of AMS 2451C. If not, the following will be of particular interest.

Who Created AMS 2451C?

Originally referred to as AMS 2451, and created in 1998, this criterion was written by SAE (SAE International) and is a standard for general brush plating requirements. After a 2011 revision, it was (and is still) referred to as AMS 2451C.

Who is SAE?

SAE is a standard developing organization and association for various industries’ engineering professionals. Spread throughout commercial-vehicle, automotive, and aerospace sectors, there are more than 128,000 related technical experts and engineers in SAE. Their mission: “To advance solutions and mobility knowledge for the benefit of humanity.”

What Is Brush Plating?

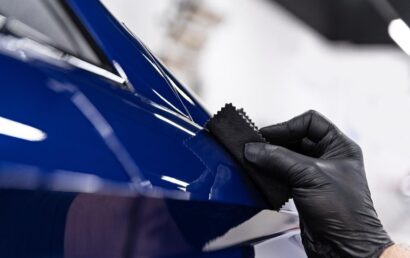

If you are involved in surface finishing, you likely already know that brush plating is a portable method of surface finishing. Its uses on manufactured components consist of the refurbishing, repair, or enhancement of localized areas. Some more specific applications of localized area brush plating are for the salvage or permanent repair of mis-machined or worn parts and the enhancement of OEM component surfaces.

You may also hear the terms brush plating and selective electroplating used in place of one another. A portable plating method used in the same manner as brush plating can be referred to as selective electroplating. The use of an immersion tank is not needed in this method for the plating of localized areas.

Why Use Brush Plating or Selective Electroplating?

The importance of electroplating lies in a number of factors. Several of these are as follows:

- The reduction of wear resistance.

- Superior protection against corrosion.

- Rather than gold, palladium can be used (at a significantly reduced cost) for the plating process.

Electroplating is used for both functional and decorative purposes. It is an excellent preventative against metal corrosion. To make certain pieces of jewelry more valuable, attractive, and durable, electroplating is sometimes used. Precious metals are taken and, through electroplating, used to cover or coat base metals.

How Do You Know If AMS 2451C (Brush Plating) Is an Option?

Brush plating may be an option if, to some or all of the following questions, you can answer yes:

- Specific to your application, is there a quality/cost/time issue?

- Is the area in need of plating localized or selective?

- In the past, have you plated to any of the following: Mil-Std QQ-S-365, Mil-Std QQ-P-416, Mil-Std 865, or AMS 2424,2423, or 2403?

More Information About AMS 2451C

For individual deposits covering nickel-tungsten, tin, cobalt, tin-zinc, zinc-nickel, silver, copper, cadmium, and nickel, AMS 2451C has a 14 slash number. Different slash numbers are associated with different deposits.

Though, in regard to the application of the process, brush plating remains very generic, it has nonetheless gained formal SAE recognition. And that’s significant.

As useful as electroplating is, the experts at A & A Coatings know that, in certain applications, thermal spraying can be just as effective, if not more so. If you would like to discuss the pros and cons of thermal spray protective coatings versus electroplating, brushed playing, etc., contact us today.