Why You Should Opt for Metallized Zinc Coatings

There can be little doubt when it comes to the positive characteristics offered by galvanized steel. That’s why it’s used in numerous industries for countless components, parts, machines, products, etc. But what if you could create something that not only met the expectations that galvanized steel meets, but exceeds them? Metallized zinc coatings can do exactly that.

Coating with Metallized Zinc

Today, a superb alternative to galvanizing, and used to coat any metal, is something referred to as zinc metallizing. Superior to that of galvanized steel, metallizing creates a superior surface ideal for paint application. It also is corrosion resistant, cost-effective, and portable.

Zinc Metallizing at Work

This is how zinc metallizing works, in a nutshell:

To form a protective coating, zinc, as a molten metal, is applied to a different metal surface like steel or iron. Easier than galvanization, this procedure doesn’t use 800°+ heated liquid vats. A mere 420° heat is required for zinc metallizing. Ordinarily, with most treated metals, this will not promote melting.

Manufacturers offering galvanization services are few and far between because of, among other things, the equipment and excruciatingly high temperature needed. But, because zinc metallizing is far less troublesome, big jobs, small jobs, and everything in between are more easily accomplished.

Should You Use Zinc Metallizing?

The answer to this is quick and easy – yes. Here are some reasons why:

- Exceptionally utilitarian for everything from construction equipment to kitchen equipment.

- For food preparation, provides a surface that is FDA approved.

- On items to be metalized, no limitation to the size.

- Extremely cost-effective.

- For items to be painted, a superior preparation surface is provided.

- Metal products can be protected against corrosion.

- Rather than waiting for a freight shipment, the process of zinc metallizing can be transported to your product because it is portable.

- In place of galvanizing, zinc metallizing is the perfect alternative.

In some cases, zinc is also being combined with other metals for particular desired coatings. One such metallized coating is zinc-aluminum, which is 15% aluminum and 85% zinc, by weight. The two behaved so well together, that studies were done to see what kind of benefits could be achieved by their combination. The result was exceptional.

Use A & A Coatings for Your Thermal Spray Zinc Metallized Coatings

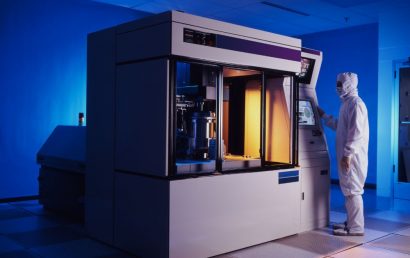

A & A Coatings has the experience and equipment necessary to enhance your project or product through the application of thermal spray zinc coatings. When it comes to the thermal spray coating industry, we have been at the forefront for over 70 years. We offer comprehensive services in addition to thermal spray such as machining, grinding, and lapping.

Our in-house capabilities include, but are not limited to:

- handling equipment and hoists to 5 tons

- sizable blasting booths

- miscellaneous honing, drilling, and milling machinery

- robotic equipment

- arc spray equipment

- hard facing equipment

- metallizing equipment

- HVOF equipment

- a metallurgical lab

- and much more

Contact one of the knowledgeable representatives of A & A Coatings today to find out how our coatings can reduce costs, help to eliminate downtime and maintenance, and generally improve your business’s bottom line.